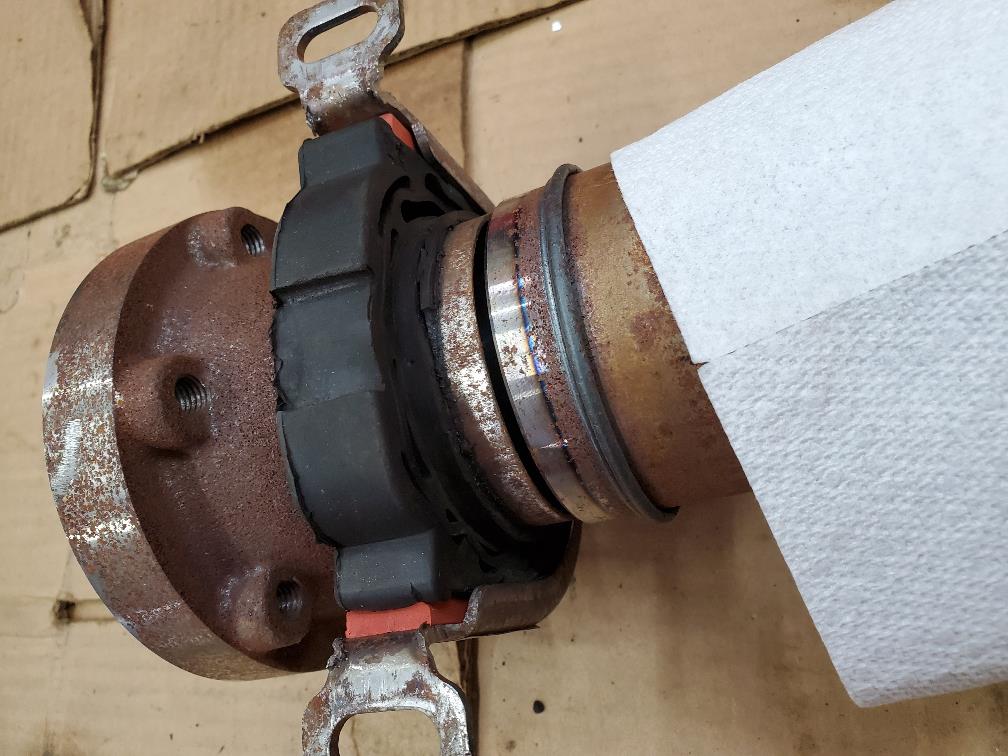

So As mentioned, I marked all three "joints" with paint before removing.

CB bushing doesn't really look horrible, it just appears it gave up it's original durometer hardness way earlier than it should have.

Kind of surprised I didn't find more info on these failing, since even just the 5.0 S197's are up to 11 years old.

Even pulling sideways as hard as I could, doesn't really reveal any damage.

I kind of hated how ford never painted their diff's over the years, so I painted mine right after I first got it home.

And I guess I painted the yellow dot on diff flange, but it looks like mine was aligned correct from the factory.

Digging around it seems like many were not, even into the S550 cars.

Got the shaft apart near the CB bushing, but there is no nut to remove to get that flange off.

I have to assume it was a pretty tight press fit, even though the center CV looks like it takes

care of telescoping, under suspension travel.

Certainly not a lot of room to get in there to press that flange off, at least not with the typical stand up press arrangement.

I do have a bearing puller setup that could be used with a press, but wondering if a real heavy duty gear puller or even

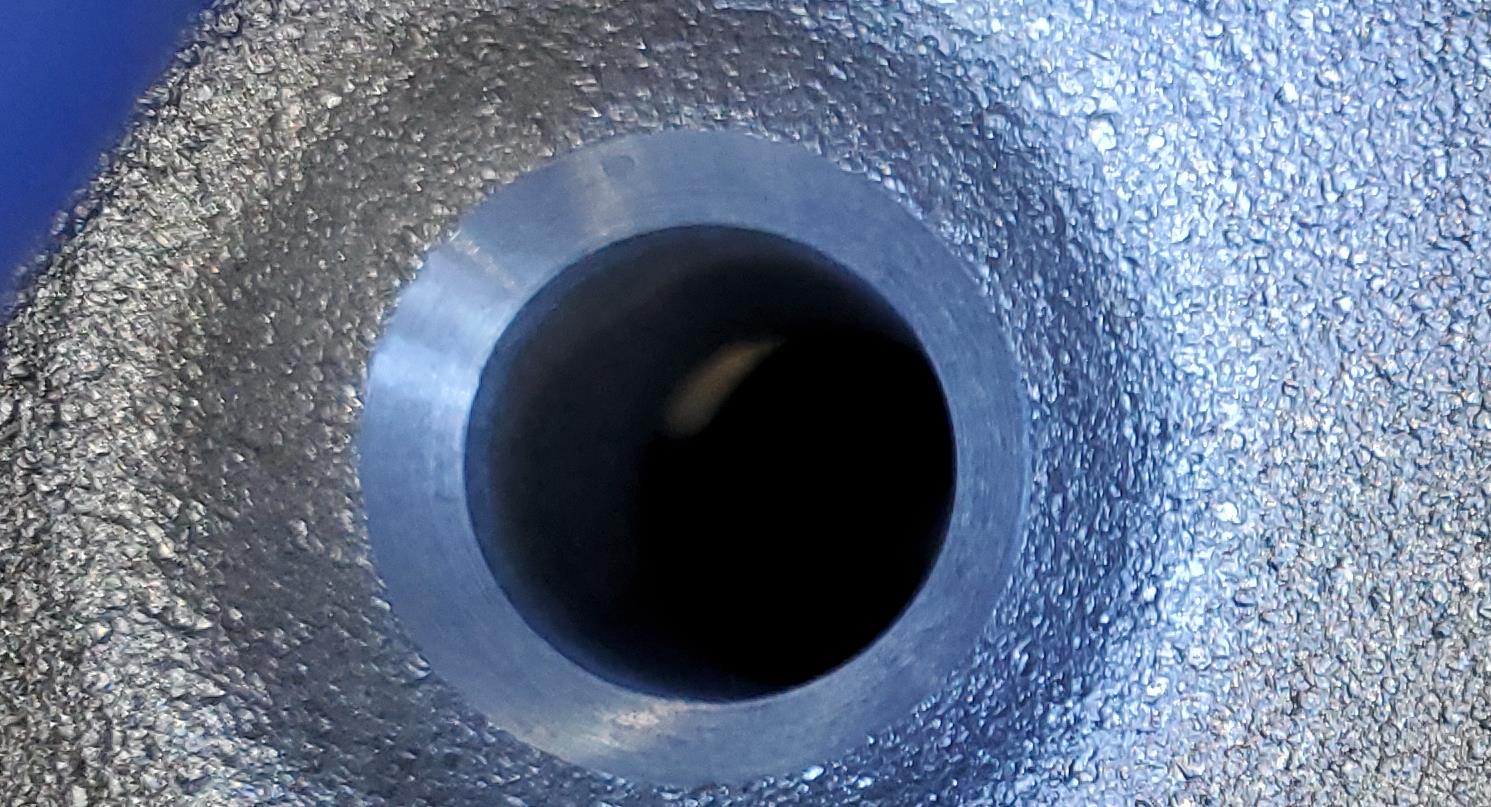

steering wheel puller might get it off. have to inspect inside of flange more closely, see if that hole in center of flange is

open and you can "push" against the rest of shaft right there.

Found two different bolt kits.

https://lmr.com/item/LRS-434496K/mustang-rear-driveshaft-bolt-kit-4r3z-4b496-aa-05-17

Definitely a difference between the pinion flange and center connection bolts.

As I mentioned, a lot of threads I searched on claim these bolts are torque to yield. It does look like I can use the longer pinion bolts in the center section, if required.

Some decent 4 July sales going on. Hope to get Summit to match a price on the new shaft I want. They have 90 day return if un-used.

Going to order a shaft and dig around locally, see if anyone can do anything with pressing off the center flange. If fixing my shaft

does not pan out, then will try the new one.